Most of the commercial works I do are small projects such as coffee shops, restaurants, and retail stores. These projects mostly use aluminum frame windows.

The good news is that I virtually never use anchors since all screws go into aluminum. The bad news is that those types of structures don’t offer flexibility as far as mounting surfaces if there is an obstruction in the way.

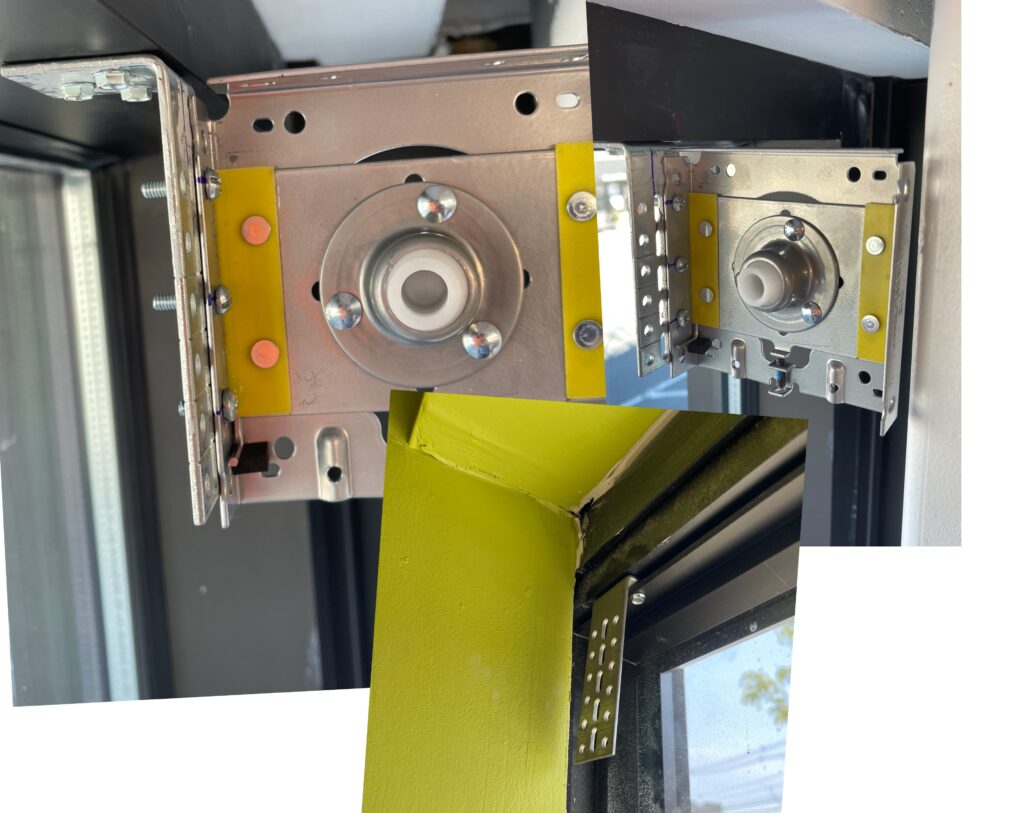

Let me explain: On those projects, it is common to encounter corner windows that share a common post or an interior wall positioned right in the middle of the window. Those situations present an extra challenge in the installation process.

Usually, installers measure window shades between mullions so there is enough space for mounting brackets on both sides.

The issue really happens when there is no mullion to attach the bracket to. In those cases, I use L brackets aka angle irons, and fasten them to the window frame. That becomes my “wall” to attach my shade brackets to.

I have two favorite L brackets in my van that meet most of my needs:

a. Support Brace – You can find them in the Rowley catalog. I use the shorter side to attach to the window frame and the larger leg to support the shade mounting bracket.

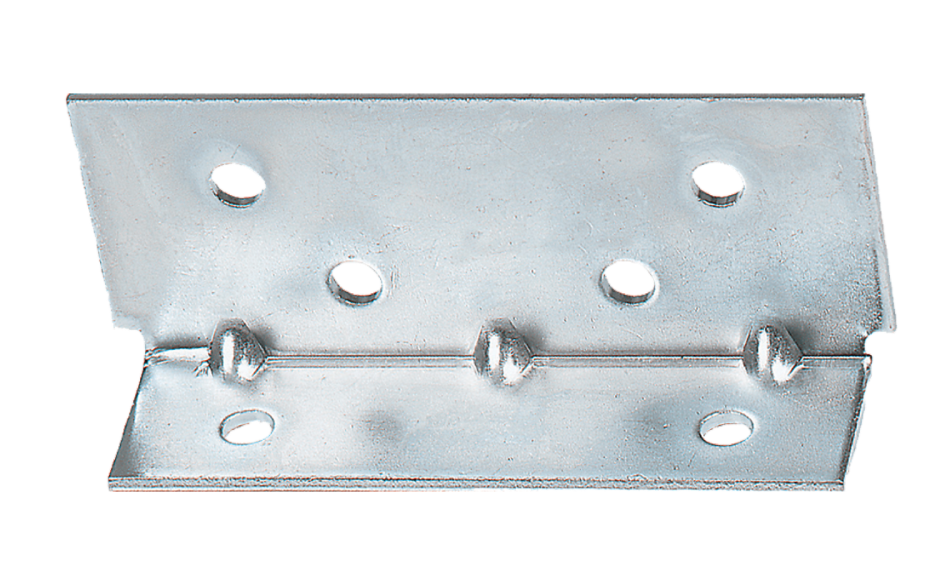

b. “L bracket” – These have a small leg that I use to secure onto the window frame and the longer leg has several holes that offer great flexibility and adjustability. They even have notches intended to be broken off in case you don’t have enough space.

These brackets are supplied by Hunter Douglas, Alta, and Comfortex when their products are ordered with extension brackets. If you are a dealer or have a relationship with one that sells those brands, ask them to order some for you as parts order.

To break off the extra length, you can bend the bracket back and forth, use a vise and a hammer at the notch, or use a cutting-off wheel.

As far as fastening the mounting brackets to the support you just installed, I suggest three options:

- Using nuts and bolts through the holes in both pieces.

- Using screws and a block of wood on the back of the L bracket to “catch” the screws.

- Using self-tapping screws directly into the L bracket (my least favorite).

I know that all great installers are creative and problem-solving creatures. I would love to hear your ideas for similar situations!